Precision Edge Profiling for High-Quality Finishes

Edge Rounding Deburring Machines are revolutionizing the way industrial components are finished by delivering consistent and smooth radius edges. These machines are essential for industries that require both aesthetic appeal and functional reliability from their metal and composite parts. With advanced engineering, Edge Rounding Deburring Machines provide flawless edge radii, ensuring products are safe to handle and meet the highest quality standards.

Seamless Integration in Production Environments

Manufacturers across various industries trust Edge Rounding Deburring Machines for their ability to integrate smoothly into existing production setups. Whether used in automotive, aerospace, or heavy machinery sectors, these machines enhance workflow by automating edge rounding tasks that were once labor-intensive and time-consuming.

Edge Rounding Deburring Machines are engineered to perform at high speeds without compromising precision. This allows operators to meet demanding production quotas while maintaining surface integrity and uniformity. Their adaptability to different material types further enhances their value, making them indispensable for high-mix, low-volume production lines.

Engineered for Uniform and Repeatable Results

Achieving a consistent radius on every part is critical for both function and safety, especially in industries where sharp edges can lead to handling injuries or assembly complications. Edge Rounding Deburring Machines deliver repeatable performance, ensuring each part is processed to exact specifications.

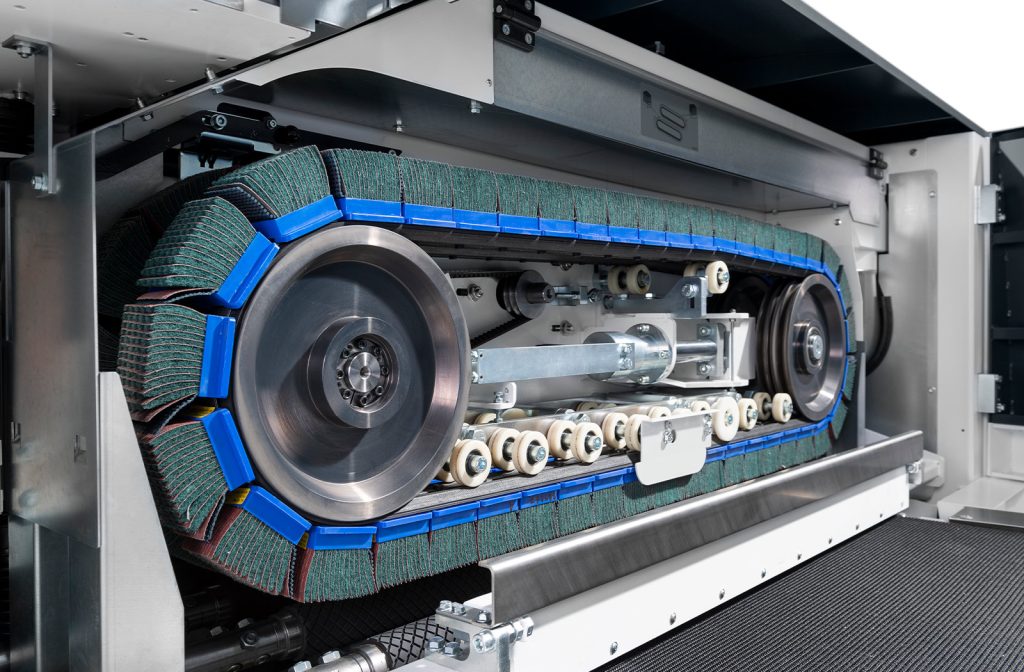

These machines utilize specialized abrasive tools and calibrated pressure settings to guarantee smooth, burr-free edges across all surfaces. This automated consistency not only reduces human error but also minimizes rework and scrap, improving overall production efficiency and cost-effectiveness.

Redefining Safety and Quality in Manufacturing

Edge Rounding Deburring Machines do more than just enhance appearance—they play a vital role in making parts safer to handle and use. Sharp burrs and rough edges can cause injuries, interfere with coating adhesion, or lead to premature wear during operation. By eliminating these imperfections, Edge Rounding Deburring Machines contribute to safer work environments and longer-lasting components.

Their capability to produce clean, radius-controlled edges also ensures parts meet strict quality certifications and industry compliance standards. Manufacturers can confidently deliver components that fulfill customer expectations and regulatory requirements.

Technological Advancements in Edge Rounding

Modern Edge Rounding Deburring Machines are built with cutting-edge features that make them both powerful and user-friendly. Advanced control systems allow operators to adjust feed rates, abrasive selection, and edge parameters with precision. These smart systems ensure each piece receives the exact edge profile it requires, regardless of size or material thickness.

From digital interface panels to automated part sensing and positioning, these machines exemplify modern innovation. Edge Rounding Deburring Machines not only simplify the finishing process but also enhance productivity and reduce downtime during batch changeovers.

Built for Durability and Industrial Strength

Constructed with rugged frames and high-grade components, Edge Rounding Deburring Machines are designed to withstand the demands of heavy-duty operations. Their industrial build quality ensures a long service life, even under continuous use across multiple shifts. This durability reduces maintenance needs and lowers total cost of ownership, making them a smart investment for manufacturers focused on long-term value.

Their compatibility with modular upgrades allows users to scale capabilities as their production demands grow, making Edge Rounding Deburring Machines a future-ready solution for evolving manufacturing landscapes.

Enhancing Surface Preparation for Secondary Processes

Consistent edge rounding is not just about finishing—it’s a critical step that affects downstream processes such as powder coating, painting, welding, and assembly. Edge Rounding Deburring Machines ensure parts have optimal surface preparation by removing micro-burrs and providing a clean, uniform edge profile.

This improvement in surface quality promotes better adhesion of coatings and ensures stronger welds, resulting in products with enhanced durability and visual appeal. Industries that rely on premium surface performance depend on Edge Rounding Deburring Machines to lay the groundwork for quality from the very start.

A Smart Choice for Global Manufacturing Leaders

Edge Rounding Deburring Machines are trusted by manufacturers around the world who value precision, reliability, and innovation. Their role in enhancing product quality, reducing manual labor, and improving operational safety has made them a cornerstone of modern manufacturing.

As global markets become more competitive, companies that invest in superior edge finishing technologies like Edge Rounding Deburring Machines gain a critical advantage. These machines not only improve product outcomes but also contribute to leaner, more efficient production environments.

Conclusion: Reliable Edge Quality Starts Here

The demand for uniform, safe, and aesthetically pleasing edges continues to rise across industries. Edge Rounding Deburring Machines offer a precise, efficient, and scalable solution for manufacturers who refuse to compromise on quality. With their advanced capabilities and rugged design, these machines deliver consistent radius edges that elevate the standard of every part they process.

For companies focused on safety, quality, and productivity, Edge Rounding Deburring Machines are the definitive choice for achieving excellence in edge finishing.